Mine-reinforced EC360 excavator drive sprocket, compatible with Lovol 360/330 wear-resistant drive sprocket, suitable for mining engineering machinery

Product Details:

| Place of Origin: | China |

| Brand Name: | QUL |

| Certification: | ISO |

| Model Number: | EC360/FR360 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | Negotiable |

| Delivery Time: | 5-8 days |

| Payment Terms: | L/C, T/T, |

| Supply Ability: | 1000+ |

|

Detail Information |

|||

| Excavator Parts: | Sprocket | Country Of Origin: | China |

|---|---|---|---|

| Processing Type: | Casting | Hardness Depth: | 8-12mm |

| Video Factory Inspection: | Able To Provide | Machinery Test Report: | Provided |

| Showroom Loion: | None | Type: | Undercarriage Parts |

| Certifiion: | ISO\CE | Part Name: | Track Drive Sprocket |

| Warranty Period: | 1 Years | ||

Product Description

EC360/Laiwo 360/330 Universal Drive Gear: Core Analysis of Mining Quality

I. Core Features: Customized for Mining Conditions •

Heavy-Duty Adaptation: The tooth profile adopts a 'deep tooth + rounded corner reinforcement' design, which is compatible with the high-intensity operations of crushing stones and hard soil in mining environments, effectively reducing the risk of tooth breakage and chipping;

General and efficient: Precisely compatible with Liewo 360/330 excavators, compatible with EC360 drive system, hole position CNC machining, direct installation without debugging, saving installation time;

Longevity Advantage: In heavy-duty mining environments, the service life is more than twice that of ordinary drive gears, reducing the frequency of equipment downtime for replacement.

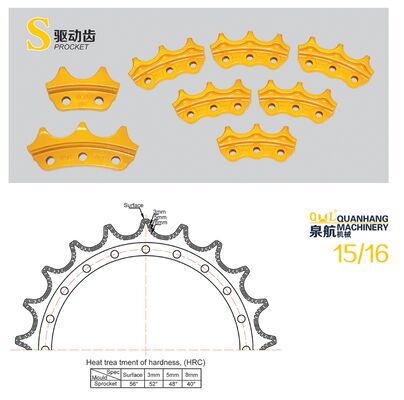

II. Process: Military-grade forging + Reinforcement treatment

Integral forging: Formed using a 1200-ton press for integral forging, avoiding stress

Carburizing and quenching process: The tooth surface undergoes deep carburizing (carburizing layer thickness 2.5-3mm) followed by high-frequency quenching treatment, achieving a surface hardness of 58-62HRC. The core maintains toughness, thus combining wear resistance and fracture resistance.

Precision Machining: Both tooth profiles and mounting holes are processed using five-axis CNC machine tools, with tolerances controlled within 0.05mm to ensure啮合精度 (meshing accuracy) with the track and sprocket.

III. Material: Mine-grade wear-resistant high manganese steel

Higher hardness: Under normal temperature, the hardness is ≥220HBW. After impact, work hardening occurs on the surface, and the hardness can be increased to above 500HBW; •

Better toughness: Fracture toughness KIC ≥ 150 MPa・m¹/², capable of withstanding frequent impacts in mining operations

Abrasion-resistant: Under gravel abrasion conditions, its wear resistance is 3-4 times that of 45# steel

IV. Core Value of Mine Quality

Adapted for heavy-duty mining scenarios to reduce equipment failure and downtime

Long service life reduces the cost of replacing parts, saving more than 60% on overall usage costs;

High meshing accuracy ensures the transmission efficiency of the equipment and reduces power loss.

驱动齿的生产工艺流程

| Production Process Flow | Production Process of Drive Gear | |

| 1 | Modeling sprocket | |

| 2 | Casting | |

| 3 | Annealing | |

| 4 | Sandblasting | |

| 5 | Drive gear rail surface quenching | |

| 6 | Tempering of the driving gear | |

| 7 | Drive turbine plus processing | |

| 8 | Prepare the paint for the drive gear | |

| 9 | Apply the drive gear | |

| 10 | The paint on the drive gear dries and is stored in the warehouse |

| Project | Detailed description | |

| Product Name | EC360 Drive Gear / Lewo 360/330 Universal Drive Gear | |

| Core Quality Tags | Mine-grade wear-resistant quality | |

| Material and Craftsmanship | High manganese steel integral forging + surface carbonitriding and quenching, hardness ≥58HRC, impact resistance and wear resistance improved by 40% | |

| Compatible models | Compatible with Lewo 360, Lewo 330 excavators, and compatible with EC360 excavator drive system | |

| Mining Working Condition Advantages | Tooth-shaped reinforcement design, suitable for heavy-duty rock crushing/earthwork operations, reduces the probability of tooth chipping/breakage, and the service life is twice that of the standard model. | |

| Installation Features | Precise CNC machining of hole positions, direct installation without adjustment, compatible with original factory chassis transmission structure | |

| After-sales guarantee | 6-month quality warranty under mining conditions, supporting return and exchange for wear detection |

Want to Know more details about this product