SH200 excavator undercarriage parts: carrier rollers, idlers, four wheels and one track, suitable for Sumitomo excavators and mining engineering machinery

Product Details:

| Place of Origin: | China |

| Brand Name: | QUL |

| Certification: | ISO |

| Model Number: | SH200 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | Negotiable |

| Delivery Time: | 5-8 days |

| Payment Terms: | L/C, T/T, |

| Supply Ability: | 1000+ |

|

Detail Information |

|||

| Excavator Parts: | Sprocket | Country Of Origin: | China |

|---|---|---|---|

| Processing Type: | Forging | Hardness Depth: | 8-12mm |

| Video Factory Inspection: | Able To Provide | Machinery Test Report: | Provided |

| Showroom Loion: | None | Type: | Undercarriage Parts |

| Certifiion: | ISO\CE | Part Name: | Track Drive Sprocket |

| Warranty Period: | 1 Years | ||

Product Description

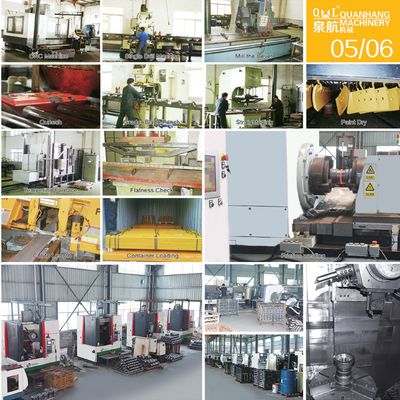

Our company specializes in the development, manufacturing (casting, forging, heat treatment) and sales of various excavator and bulldozer chassis parts such as idler wheels, towing wheels, drive teeth, guide wheels, track assemblies, U-shaped frames, knife Angle plates, well frames, bucket connecting rods, guard chains, tensioning cylinders, track plates, pins, bucket shafts, shaft sleeves, etc. Our company is equipped with advanced domestic production facilities and testing methods, and adopts Leading process flow. With first-class quality, rich varieties, reasonable prices and good reputation, we have received high praise from a wide range of customers. Our products are sold both at home and abroad. We have established long-term and good cooperative relationships with distributors from various countries such as Russia, Turkey, Iran, India, Malaysia, Thailand, Vietnam, Indonesia, Egypt, Bolivia, Kenya, Uganda and Ghana. Our company adheres to the business tenet of striving for excellence and continuous innovation, and upholds the concept of "quality first, technology supreme, continuous improvement and common development". We aim to open up the future with high quality and provide customers with comprehensive and high-quality services.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Production process flow of track rollers and carrier rollers

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | |

| Wheel body | Wheel forging |

Shell Q&T |

Rough machining | Rail surface quenching | Wheel body assembly welding | Precision turning of the wheel body | Semi-product |

| End cover | Collar pouring | Nodulizing | Shot blasting | Machining | Cleanig Ant-rust | Semi-product | |

| Shaft | Shaft cutting | Shaft Q&T | Rough machining | Hardening | Tempering | Grinding | Semi-product |

| Assembly | Air leakage testing | Oil filling | Initial run | Painting | Package and storage | ||

Want to Know more details about this product