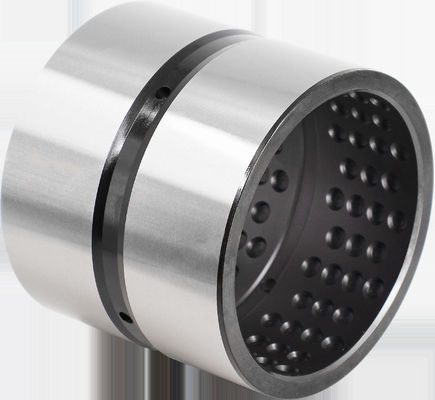

Industrial Kubota Kx121 3 Pins And Bushings For Excavator

Product Details:

| Place of Origin: | Shandong, China |

| Model Number: | 001 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100 pieces |

|---|---|

| Price: | $0.60/pieces 100-499 pieces |

| Packaging Details: | Plastic packaging |

| Supply Ability: | 200000 Piece/Pieces per Month |

|

Detail Information |

|||

| Applicable Industries: | Manufacturing Plant, Manufacturing Plant, Machinery Repair Shops, Construction Works | Type: | Sleeve |

|---|---|---|---|

| Material: | Steel, Stainless Steel | Size: | Customzied |

| Processing: | CNC Processing | Operating Temperature: | -100~+350℃ |

| Feature: | Good Lubricating Storage Of Oil | Application: | Excavators,Loaders ,Construction Machine |

| Highlight: | Industrial kubota kx121 3 pins and bushings |

||

Product Description

Excavator Loader Spare Parts Mesh Thread With Clean Oil Channel Steel Bushing

Digger bushings, also known as digger pivot bushings or digger boom/arm bushings, are specific types of bushings used in diggers, which are heavy machinery commonly used in construction and excavation projects. These bushings serve similar purposes as excavator bushings, providing support, reducing friction, and absorbing shock between the moving parts of the digger's boom, arm, and bucket assembly. Here are some key features and considerations related to digger bushings:

-

Material: Digger bushings are typically made from durable materials such as hardened steel or bronze alloys. The material choice depends on factors such as the application, load capacity, operating conditions, and desired level of wear resistance.

-

Design considerations: Digger bushings come in various designs, including cylindrical or flanged bushings. The design choice depends on the specific application and the type of movement or load that the bushing needs to accommodate.

-

Load capacity: Digger bushings are designed to withstand high loads encountered during digging and excavation operations. They provide support and stability to the boom, arm, and bucket assembly, ensuring efficient and reliable performance.

-

Wear resistance: Digger bushings are subjected to continuous movement and heavy loads, leading to wear over time. The materials used for these bushings are chosen for their wear resistance properties, allowing them to withstand the abrasive forces encountered during digging and excavation work, and provide extended service life.

|

Performance Index

|

|

Data

|

|

|

Hardness

|

HRC

|

58-62

|

|

|

Max Load

|

N/mm2

|

250

|

|

|

Max Linear Velocity

|

m/s

|

0.1

|

|

|

Max PV Value

|

N/mm2.m/s

|

1.5

|

|

|

WorkingTemperature Limit

|

℃

|

-100~ +350

|

|

|

Linear Expension Coefficient

|

10-5/℃

|

1.1

|

|

|

Performance Index

|

|

Data

|

|

|

Hardness

|

HV

|

≥650

|

|

|

Max Load

|

N/mm2

|

200

|

|

|

Max Linear Velocity

|

m/s

|

0.1

|

|

|

Max PV Value

|

N/mm2.m/s

|

1.5

|

|

|

WorkingTemperature Limit

|

℃

|

-100~ +350

|

|

|

Linear Expension Coefficient

|

10-5/℃

|

1.1

|

|

|

Performance Index

|

|

Data

|

|

|

Hardness

|

HV

|

≥650

|

|

|

Max Load

|

N/mm2

|

200

|

|

|

Max Linear Velocity

|

m/s

|

0.1

|

|

|

Max PV Value

|

N/mm2.m/s

|

1.5

|

|

|

WorkingTemperature Limit

|

℃

|

-100~ +350

|

|

|

Linear Expension Coefficient

|

10-5/℃

|

1.1

|

|

|

Material and bushing

characteristics |

|

value

|

Company

|

value

|

|

|

Maximum load

|

Mpa

|

100

|

psi

|

145,00

|

|

|

working temperature

|

℃

|

-40 to 300

|

°F

|

-40 to 572

|

|

|

Max Linear Velocity

|

m/s

|

0.5

|

fpm

|

100

|

|

|

Maximum PV Value

|

m/sxMPa

|

1.65

|

pis x fpm

|

48,000

|

|

|

Minimum hardness of sliding layer

|

HB

|

210

|

HB

|

210

|

|

|

Minimum hardness of dual parts

|

HRC

|

40

|

HRC

|

40

|

|

full container load and LCL container (less than a container load) can be acceptable.We accept the sample and trial order. If the quantity of single item can't reach the MOQ, the price should be sample price.

hours. Our advantages are multiple resource integration, strong quality assurance and excellent service level. We are always responsible for our products.